Overview

G.O.R.M. is the latest iteration of the AAU Mars rover and the first to adopt a naming convention inspired by the ancient kings of Denmark. This generation represents a major refinement of the existing rover platform, specifically engineered to be more competitive in the European Rover Challenge (ERC). The development focused on improving efficiency, modularity, and durability while adhering to weight and performance constraints set by the competition. One of the most significant changes was the overhaul of the power system. The battery pack was redesigned, resulting in an 80% reduction in weight compared to previous versions. While this drastically improved the mass distribution and mobility of the rover, it also limited the operational time to around four hours—still sufficient for ERC task durations. To support this change, the entire internal electronics layout was restructured to enhance system reliability and enable quicker payload swaps or component upgrades. The mechanical structure also received considerable upgrades. All 3D-printed components were redesigned for improved strength and ease of manufacturing, and the printing material was changed from PLA to PETG. This change provided increased thermal resistance and mechanical durability, better suited for outdoor and rugged testing environments. Combined with the new chassis design and optimized part layout, these updates allowed the fully equipped rover—with manipulator and additional attachments—to maintain a total weight of approximately 70 kg, well within ERC limits.

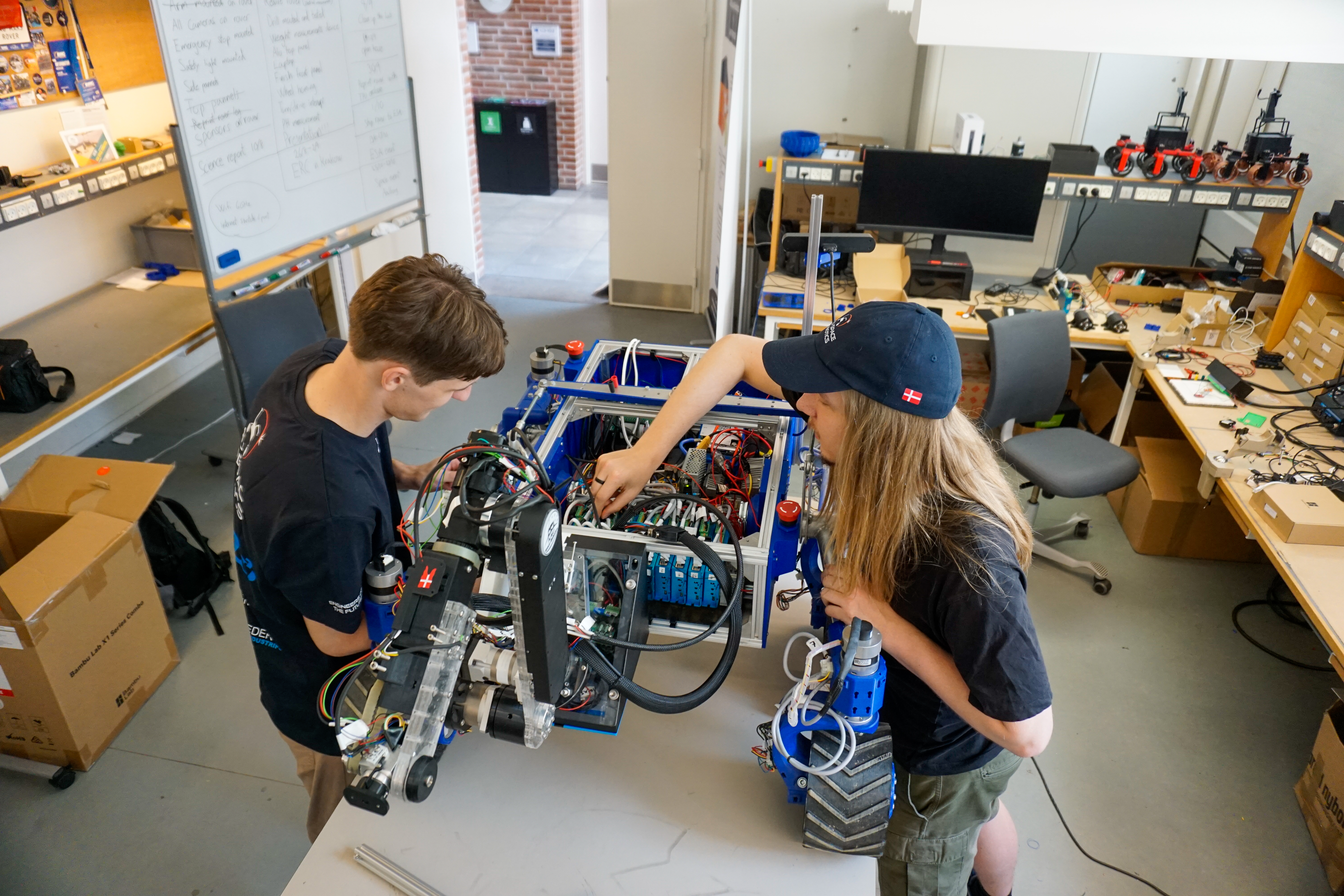

Mechanical Design

The mechanical design of the G.O.R.M. rover emphasizes modularity, robustness, and adaptability to the terrain and task demands of the European Rover Challenge. The rover's main body is built on a rigid square frame made from lightweight aluminum extrusion, chosen for its balance of strength, weight, and ease of modification. The frame is enclosed with 3D-printed PETG plates, which provide protection for internal components while keeping the system lightweight and resistant to impact and weather exposure. The mobility system is based on the NASA-proven rocker-bogie suspension, allowing the rover to maintain stability and traction over uneven terrain by keeping all six wheels in contact with the ground. The drive system consists of six wheels, four of which are steerable, enabling the rover to utilize both Ackermann steering for efficient turning at speed and turn-on-the-spot rotation for tight maneuvering. This dual-mode steering configuration greatly enhances the rover's agility in confined or obstacle-filled environments. A key feature of the mechanical design is the detachable front module, which allows the manipulator arm and its associated electronics to be mounted or removed easily depending on mission requirements. This modular approach simplifies maintenance and makes the rover highly adaptable to task-specific configurations. The manipulator itself is a six-degree-of-freedom robotic arm, inspired by the open-source AR4 design from Annin Robotics. It is constructed using a combination of laser-cut acrylic and 3D-printed PETG components. The arm is fitted with a custom-designed gripper capable of measuring grip strength via an integrated strain gauge, as well as performing pH measurements allowing it to support both mechanical and scientific tasks during ERC challenges. At the rear of the rover, a detachable drill system is mounted for soil sample collection. This drill combines mechanical augering with an air pressure-based vacuum system that loosens and transports material through a tube. A cyclone separator then extracts the sample from the airflow and deposits it into a dedicated storage container. This container includes an onboard weighing system that allows the rover to measure the collected sample mass autonomously.

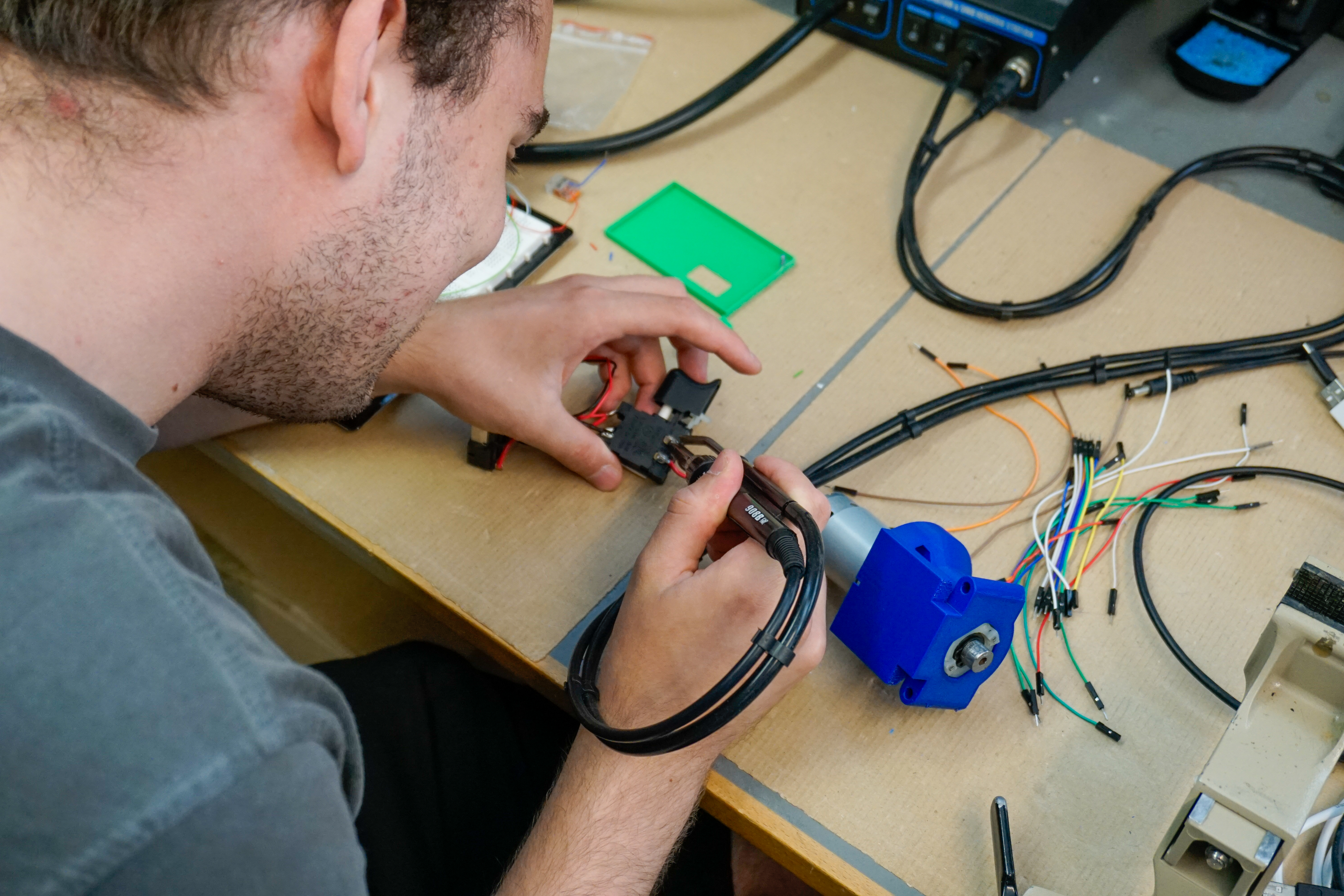

Electrical Design

The electrical system of the AAU Space Robotics rover is designed for modularity, reliability, and safety. It is powered by a 32V, 20Ah lithium-ion battery that supplies energy to the motors, electronics, and manipulator via a custom power distribution PCB. Power usage is efficiently managed, with ten 24V motors drawing up to 800W, a 200W robotic arm, and 100W allocated for computing systems. Communication relies on the CANopen protocol for motor controllers, with redundancy ensured through a Jetson Orin computer and a backup Raspberry Pi using a USB-to-CAN interface. The manipulator is housed in a separate electronics module connected by power, USB, and emergency stop lines. It is controlled by a Teensy 4.1 microcontroller that drives the stepper motors and processes sensor input. The gripper operates independently using an Arduino Nano and includes a strain gauge for force feedback. Safety is prioritized through a hardware emergency stop that cuts power within one second and a heartbeat protocol that halts movement if CAN communication fails. Loss of connection to the ground station also triggers an automatic stop. The modular system allows for easy maintenance and quick component replacement in the field.

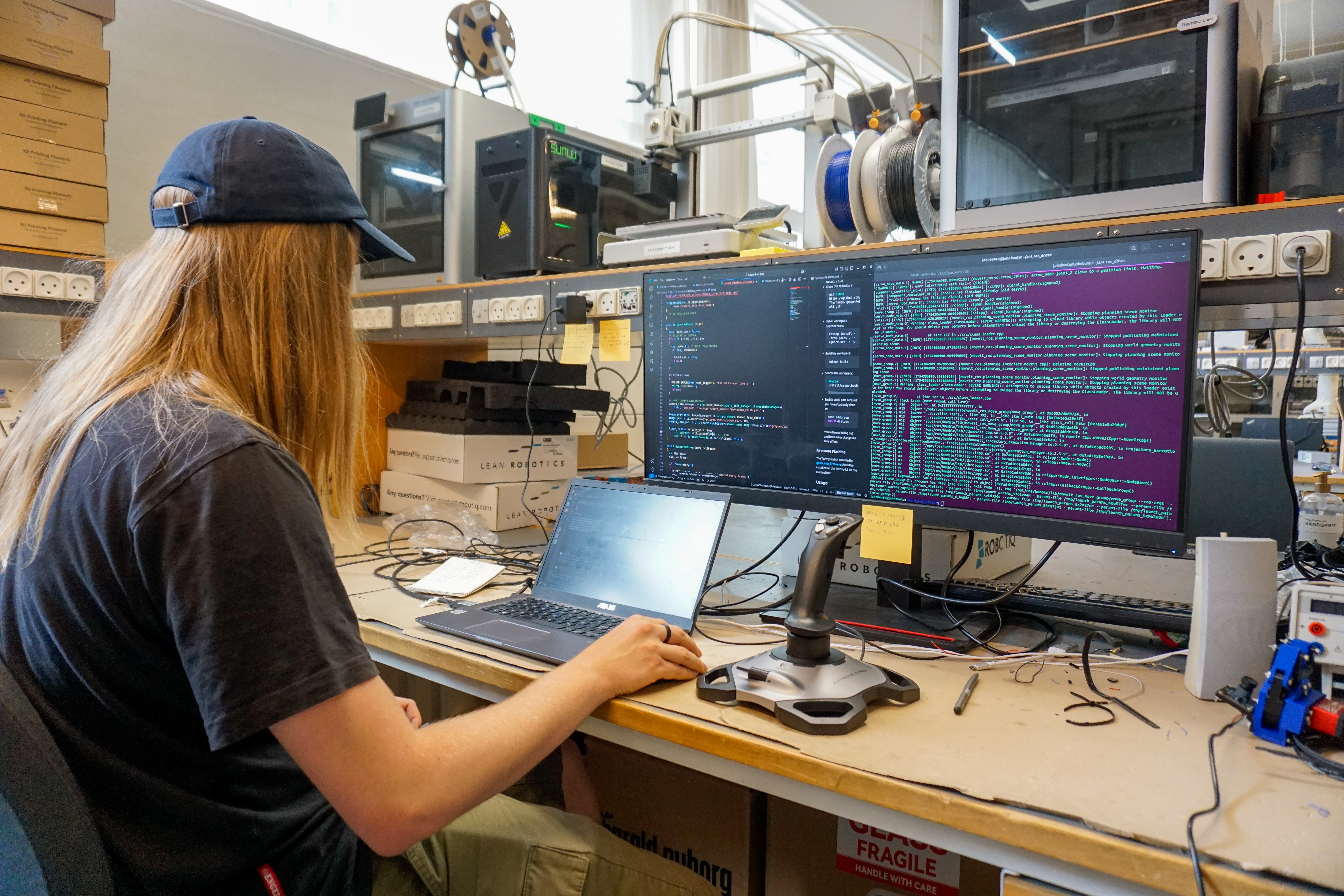

Software Design

The software system of the AAU Space Robotics rover is built on the ROS 2 framework, enabling modular and scalable development. It is divided into two main stacks: navigation and manipulation. The core runs on a Jetson Orin computer, which handles autonomous movement, motor control via CANopen, and high-level decision-making. For the manipulator, the Jetson communicates with a Teensy 4.1 microcontroller over USB, sending commands and receiving joint state feedback in real time. Navigation software includes path planning, localization, and obstacle avoidance. It uses sensor data from cameras and LiDAR, combined with reinforcement learning in a teacher-student neural network setup, to enable intelligent path following in complex environments. Computer vision is handled by convolutional neural networks trained to detect and classify rocks, aiding both navigation and sample collection. The gripper and manipulator motion are integrated through MoveIt and custom ROS 2 hardware interfaces. Safety mechanisms are also embedded in the software stack, such as watchdog timers and emergency stop handling, ensuring the rover halts safely during critical faults.